|

|

|

|

ANTI COMPRESSION POST & SALOON TABLE DESIGNED AND FITTED IN A HURLEY FELICITY Kevin Mitchell Joiner 'WOODWORX' Gerry Arbon the current owner of Celtic Nomad, a smart little Hurley Felicity commissioned me in the latter part of last year to fit an anti compression post into his boat. At the time he had released the tension on his shrouds and was gradually raising the cabin roof using a scissor jack and short post. My design incorporated a special head fitting which comprised a block of solid mahogany with four holes cut out to accommodate the nuts on the underside of the mast base plate and also a shallow raised edging for the post to fit into to prevent it sliding around. The bottom of the post rests flat and centrally in the bilge and sits on a thin bead of Sikoflex. Gerry then finished it off by glassing around the base. The end result looks as though it has always been there but did require me to cut two new pieces of plywood flooring to fit around the post and the old carpet was carefully prized away form the discarded boards and then re fitted to the new wood.

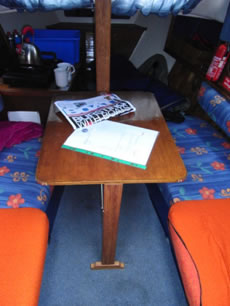

Saloon Table Having successfully completed the anti compression post I was asked if I could design and make a small saloon table and thought to make use of the plywood left over from the new floorboards. I discussed with Gerry my ideas which would incorporate a fitting attached to the new post which would allow the table to be attached or taken down for storage when not in use. The table top was cut and the corners rounded then hardwood edging applied to the flat parts of the edge and finally four pieces of brass strip were cut, drilled and bent to a former before being attached to each corner. Next a leg was made which is held in place by a long T hinge and to ensure the leg does not fold inward when in use a desk type stay was fitted. The leg is pulled downwards to its optimum position then the stay which folds, is opened and locks. From Metals South West in Newton Abbot I bought a 50mm long piece of 38 x38mm right angle solid brass one edge of which I rounded both corners and then drilled a central hole for an 8mm bolt. On the other face two holes were drilled and countersunk for screwing to the post. When the brass was ready I polished it to a high sheen. The bolt passes through the table top and down through the brass plate and is secured with a wing nut. To ensure even pressure on the wood of the table I glued a penny washer up under the head of the bolt using plastic steel. When the table is not in use it stows under the cushion at the foot end of one of the berths.

WOODWORX

would be pleased to quote you for any 'one off' specialist joinery jobs |